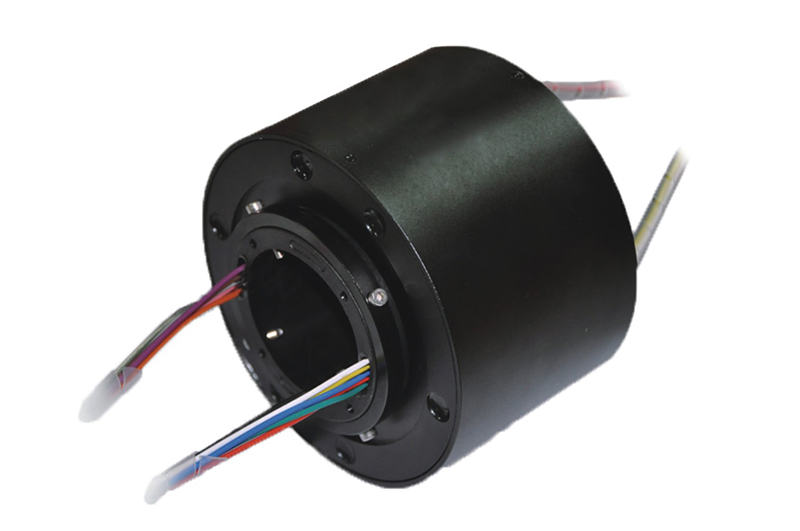

Through Bore Slip Rings

A through bore slip ring allows 360° free transmission of power, signal / data from a stationary device to a rotary device while provides routing space in the center for hydraulic/ pneumatic lines or shaft mounting. The central through bore space also can be integrated with a FORJ or coaxial rotary joint to provide an integrated solution for the system. AOOD provide 3mm to 190mm standard through bore design to meet the need of different applications, including 3mm, 7mm and 12mm bore miniature through bore slip rings to satisfy some systems’ mounting and low current or signal / data transfer requirement. Larger diameter or high protection solutions can be customized. Robust configuration and low noise low wear multi-points contact fiber brush technology allows it to be the ideal slip ring solution in both industrial and military fields.

Features

■ 3mm to 190mm through bore optional

■ Up to 800 circuits

■ Compatible with various data protocols

■ Capable of handling high current or high power circuits

■ Flexible combination of power and signal transfer

■ Standard collar mounting or custom flange mounting optional

Advantages

■ Can transmit multiple signals / data and high currents simultaneously

■ Modular design to meet the specific requirements

■ Rugged structure and steady transmission

■ Maintenance-free and long lifetime

Typical Applications

■ Packaging and wrapping machinery

■ Semiconductor handling systems

■ Robotics

■ Heavy equipment turrets

■ Cable reels

■ Palletizing machines

| Model | Rings | Rated Current | Rated Voltage | Size | Bore | Speed | |||||

| 2A | 5A | 10A | 120V | 240V | 380V | OD (mm) | L (mm) | ID (mm) | RPM | ||

| ADSR-F3-24 | 24 | × | × | 22 | 51.6 | 3 | 300 | ||||

| ADSR-F7-12 | 12 | × | × | 24.8 | 26.6 | 7 | 300 | ||||

| ADSR-F15-12 | 12 | × | × | 32.8 | 41.7 | 15 | 300 | ||||

| ADSR-F15-24 | 24 | × | × | 32.8 | 41.7 | 15 | 300 | ||||

| ADSR-T12 | 6 | × | × | 55 | 33.8 | 12.7 | 300 | ||||

| 12 | × | × | 47.6 | 300 | |||||||

| 18 | × | × | 61.4 | 300 | |||||||

| 24 | × | × | 75.2 | 300 | |||||||

| ADSR-T25A | 6 | × | × | 78 | 48 | 25.4 | 300 | ||||

| 12 | × | × | 72 | 300 | |||||||

| 18 | × | × | 96 | 300 | |||||||

| 24 | × | × | 120 | 300 | |||||||

| ADSR-T25B | 6 | × | × | 78 | 36 | 300 | |||||

| 12 | × | × | 48 | 300 | |||||||

| 18 | × | × | 60 | 300 | |||||||

| 24 | × | × | 72 | 300 | |||||||

| 36 | × | × | 84 | 300 | |||||||

| ADSR-T38A | 6 | × | × | 99 | 48 | 38.1 | 300 | ||||

| 12 | × | × | 72 | 300 | |||||||

| 18 | × | × | 96 | 300 | |||||||

| 24 | × | × | 120 | 300 | |||||||

| ADSR-T38B | 6 | × | × | 99 | 36 | 300 | |||||

| 12 | × | × | 48 | 300 | |||||||

| 18 | × | × | 60 | 300 | |||||||

| 24 | × | × | 72 | 300 | |||||||

| 36 | × | × | 84 | 300 | |||||||

| ADSR-T50A | 6 | × | × | 119 | 54 | 50 | 300 | ||||

| 12 | × | × | 78 | 300 | |||||||

| 18 | × | × | 102 | 300 | |||||||

| 24 | × | × | 126 | 300 | |||||||

| ADSR-T50B | 6 | × | × | 119 | 42 | 300 | |||||

| 12 | × | × | 54 | 300 | |||||||

| 18 | × | × | 66 | 300 | |||||||

| 24 | × | × | 78 | 300 | |||||||

| 36 | × | × | 90 | 300 | |||||||

| ADSR-T70 | 6 | × | × | × | 138 | 53 | 70 | 300 | |||

| 12 | × | × | × | 71 | 300 | ||||||

| 18 | × | × | × | 89 | 300 | ||||||

| 24 | × | × | × | 107 | 300 | ||||||

| ADSR-T80 | 6 | × | × | × | 148 | 80 | 300 | ||||

| 12 | × | × | × | 300 | |||||||

| 18 | × | × | × | 300 | |||||||

| 24 | × | × | × | 300 | |||||||

| ADSR-T100 | 6 | × | × | 186 | 133.2 | 101.6 | 300 | ||||

| 12 | × | × | 217.2 | 300 | |||||||

| 18 | × | × | 301.2 | 300 | |||||||

| 24 | × | × | 385.2 | 300 | |||||||

| Remark: More circuits, speed, higher current / voltage and higher protection can be customized. FORJ and coaxial rotary joint can be integrated. | |||||||||||